And that's typically put on the map as a kaizen burst. With the analysis done, and based on the experience of the people in the room, we start identifying opportunities for improvement. Once a current state is done, there might be some hand calculations or perhaps some spreadsheet calculations for the key metrics like lead time, takt time, inventory & capacity, that help quantify areas of waste. Typically, post-it notes might be used for something like this. The team walks the value stream, if possible, collecting the data live, and then they create a wall map. A value stream charter is created in advance, so the goals as well as the start and end points of the map are clear for everyone.

It's a physical event that starts with a wall mapping activity, with people gathered in a room. Let's start with looking at the traditional VSM event and improvement cycle, something we have seen in many companies. For companies who have standardized on Google-based collaboration, a Google drawing based tool for remote VSM has been developed also.

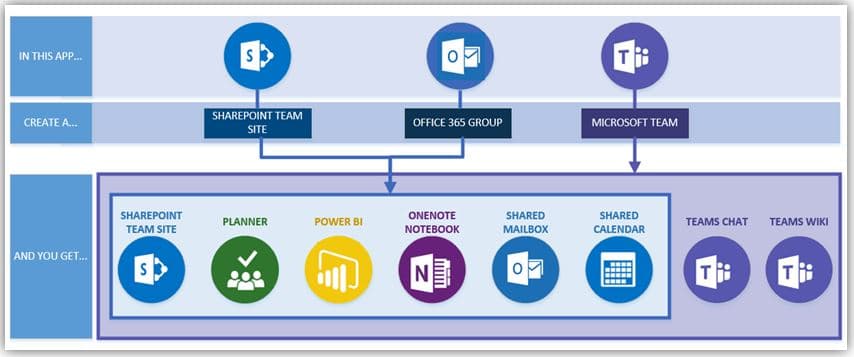

Our group has created a solution for VSM capture and analytics in this remote environment, leveraging Microsoft Teams and the Microsoft OneNote collaborative application.

The ability to hold VSM events in a remote manner, (where its not possible to co-locate the team physically) has become increasingly important.

0 kommentar(er)

0 kommentar(er)